Difference Between Hot & ColdRolled Steel PA Steel

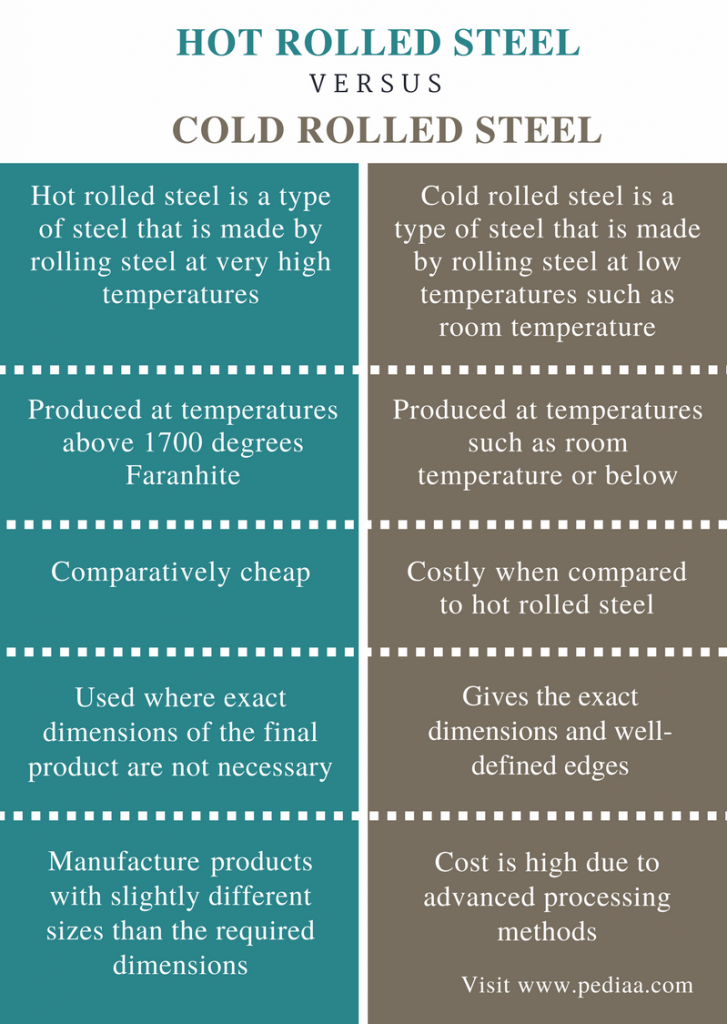

Cold rolled steel. Cold worked steels are typically harder and stronger than standard hot rolled steels. Cold rolled steel is essentially hot rolled steel that has been through further processing. Once hot rolled steel has cooled, it is then re-rolled at room temperature to achieve more exact dimensions and better surface qualities.

Hot Rolled vs Cold Rolled Steel Alliance Steel

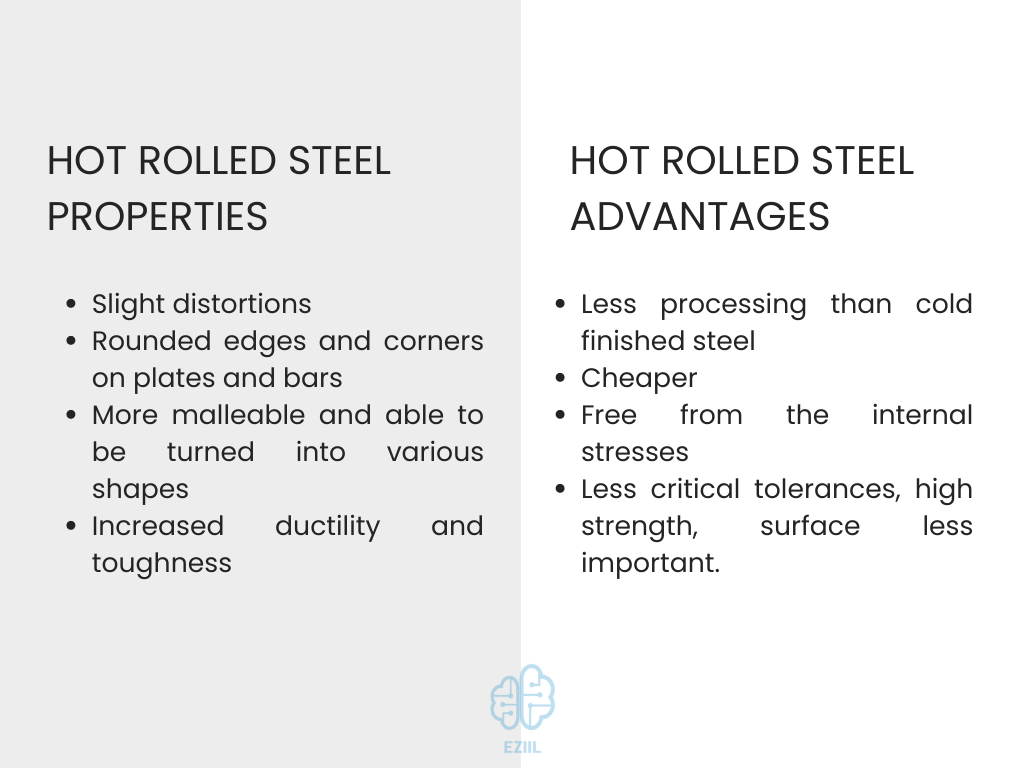

Hot Rolled Steel is softer and more pliable than Cold Rolled Steel. Hot Rolled Steel has a light- grey, rough finish and rounded edges (in Flat and Square Bars ), and Hot Rolled products are typically oversized. Hot Rolled steel bars are used in the welding and construction trades where the items being constructed do not require super precise.

Hot Rolled vs Cold Rolled Steel Key Differences Between Them

Hot vs. cold rolled steel Hot Rolled Steel. As one might have assumed, the primary difference between hot and cold rolled steel is the temperature at which the manufacturing process occurs. Hot rolled steel is processed at over 1,700°F and is easier to work with because, although steel gets red hot at 900 °F, it recrystallizes between 750°F.

Difference between hot rolled steel and cold rolled steel?

Hot Rolled Steel: It's processed at very high temperatures, typically over 1,700°F. This method allows easier forming as steel recrystallizes at these temperatures. The result is steel with scale, which can be removed through pickling and oiling. Cold Rolled Steel: Cold rolling occurs at or near room temperature.

Hot Rolled Steel Vs. Cold Rolled Steel Sciencing

The pronounced dissimilarities between hot-rolled steel and cold-rolled steel make them suitable for diverse applications. Image Credit: Masteel UK Ltd. Hot-Rolled Steel. Hot rolled steel undergoes roll pressing at extremely high temperatures, often exceeding 926 °C or 1700 °F, surpassing the standard recrystallization temperature of steel.

Hot rolled steel vs cold rolled steel what's the difference?

This post will explain the four different steel forming process: hot rolled steel, cold rolled steel, forged steel and cast steel. And discuss the advantages and applications of each steel forming process, and will tell you how to buy the right steel materials in great quality and price. Steel Forming Process 1 - Hot Rolled Steel.

Difference Between Hot Rolled and Cold Rolled Steel Definition, Production, and Benefits

Generally, hot rolled steel has a rougher, more scaly finish that can also include slight distortions and non-uniformities in shape. The cooling process can result in shrinkage and slightly less precise dimensional accuracy. Cold-rolled steel features a much smoother, more polished, and aesthetically pleasing finish.

Hot Rolled Steel, Cold Rolled Steel & Cold Drawn Steel Steel Available

Hot-rolled and cold-rolled steel is produced differently. Hot rolled steel is made by heating steel above its recrystallization temperature, typically between 1,100°F and 1,800°F. The steel is then fed through a set of rollers to achieve the desired thickness, creating a sheet or coil of steel.

What is the Difference Between Hot Rolled (HR) & Cold Rolled (CR) Steel?

The main difference between hot- and cold-rolled steel lies in their manufacturing processes: Hot-Rolled Steel. Hot rolling is a metalworking process that happens above the steel's recrystallization temperature—usually over 1,700 degrees Fahrenheit. During the process, steel is fed into rolling mills at these high temperatures to achieve a.

Cold Rolled Vs. Hot Rolled Steel RMT Revolution Machine Tools™

Hot rolled steel involves rolling steel at high temperatures, while cold rolled steel refers to processes done at or near room temperature. Certain types of steel will work better with certain applications, so understanding the differences between the hot rolling and cold rolling processes can help save time and money, eliminating unnecessary.

Hot Rolled Steel, Cold Rolled Steel & Cold Drawn Steel Steel Available

The terms "hot-rolled steel" and "cold-rolled steel" don't refer to a specific type of steel. Rather, they refer to the way in which steel is produced. With hot rolling, molten steel is pressed at extremely high temperatures, typically reaching or exceeding 1,700 degrees Fahrenheit. This is important because steel recrystallizes at.

Cold Rolled Steel Cold Rolling vs Hot Rolling Hot Rolled Steel YouTube

Hot rolled steel is more suitable for large structural components which do not have tight tolerances and aesthetic requirements. However, cold rolled steel will be the best choice if you need smaller parts requiring durable and more precise qualities. Cold rolled steel is also stronger and harder than hot rolled steel.

Hot Rolled vs Cold Rolled Steel Understanding the Differences ETCN

While hot rolled steel is prized for being flexible and easy to work with, cold rolled steel does not undergo the same process that allows this particular feature. As a result, it is much stronger than the other and comes out of the rolling process about 20% harder. Cold rolled steel also has the advantage of being used in jobs that require.

Hot Rolled vs Cold Rolled Steel Metal Casting Blog

The advantages of cold rolled steel include its superior surface finish, higher strength, and tighter dimensional tolerances compared to hot rolled steel. However, the increased strength and reduced ductility of cold rolled steel can make it more challenging to work with in certain fabrication processes than hot rolled steel.

Hot Rolled vs. Cold Rolled Weathering Steel Central Steel Service Inc.

Cold-Rolled Steel Applications Within the cold rolling process, steel sheet is cooled at room temperature (after hot rolling) and is then annealed or tempers rolled. Although "cold rolled steel" is a specific type of steel, the term is often used to mean all kinds of carbon steel materials. Cold-rolled steel applications include: Sheet & Plate

Cold Rolled Steel Vs. Hot Rolled Steel by Tuell & Reynolds YouTube

Thus, the yield strength of cold rolled steel is higher than that of hot rolled steel. As an example, a hot rolled steel product may have a yield strength of 235 MPa. In comparison, a cold rolled steel product with the same chemical composition has a yield strength of 365 MPa. The main advantages of cold working are: Accurate finished dimensions.

.